CNC Vision Measuring Machine With Renishaw MCP Probe (APC300)

The CNC vision measuring machine is used for 2D measurement, when it adds a probe, it can be used as the Coordinate measuring machine(CMM) for 3D size, such as height, depth, flatness and so on.

CNC Vision Measuring Machine Features & Advantages

1. Servo motor, high positioning accuracy and smooth movement

2. Advanced Navitar 0.7-0.45x zoom lens

3. SENTECH Color 1/2 CCD Camera

4. Joystick and mouse operation, easy to use

5. Granite base 6. Programmable LED cold lights

6. Automatic measuring software

7. Fast Auto Focus

8. Renishaw MCP Probe

Technical Data

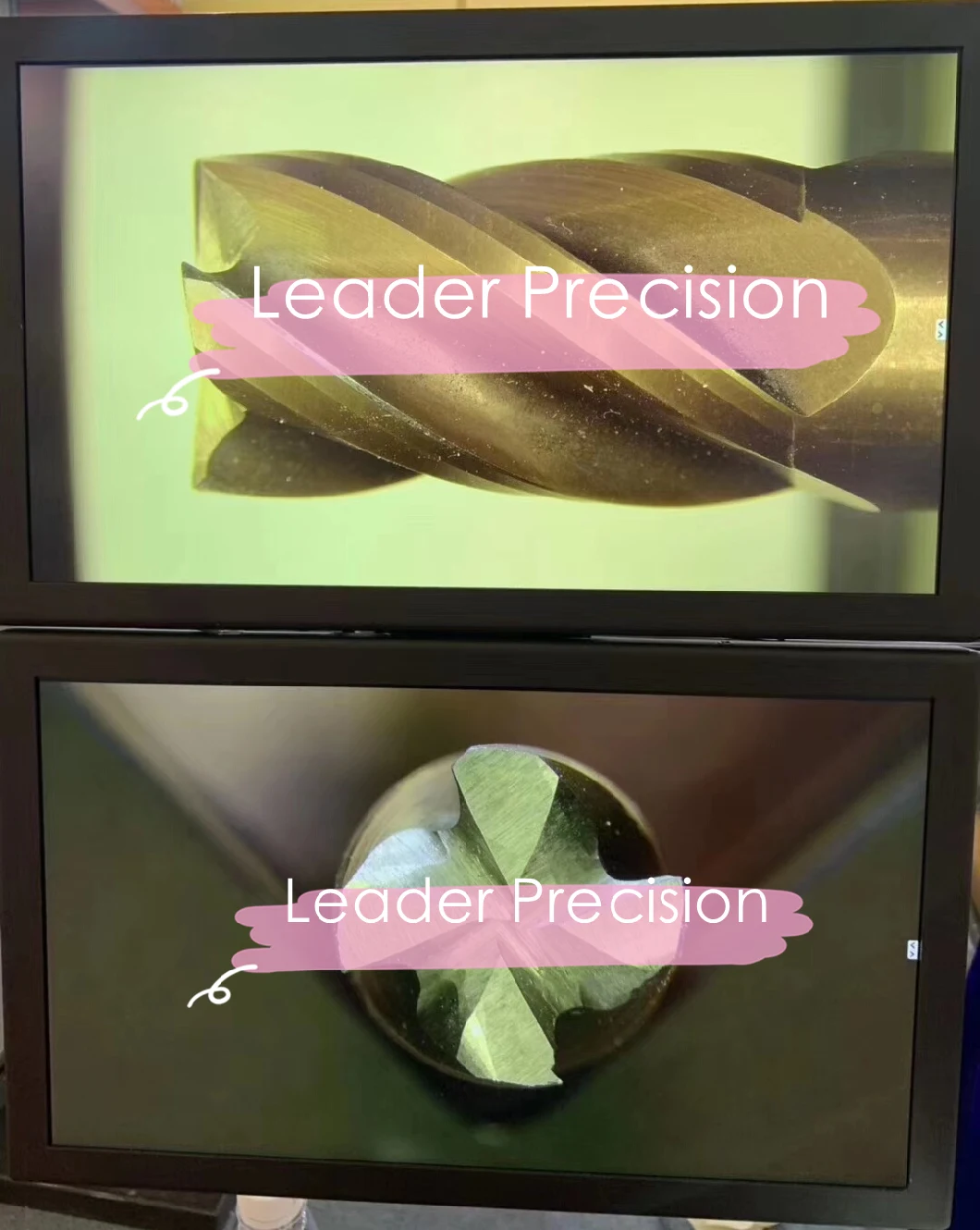

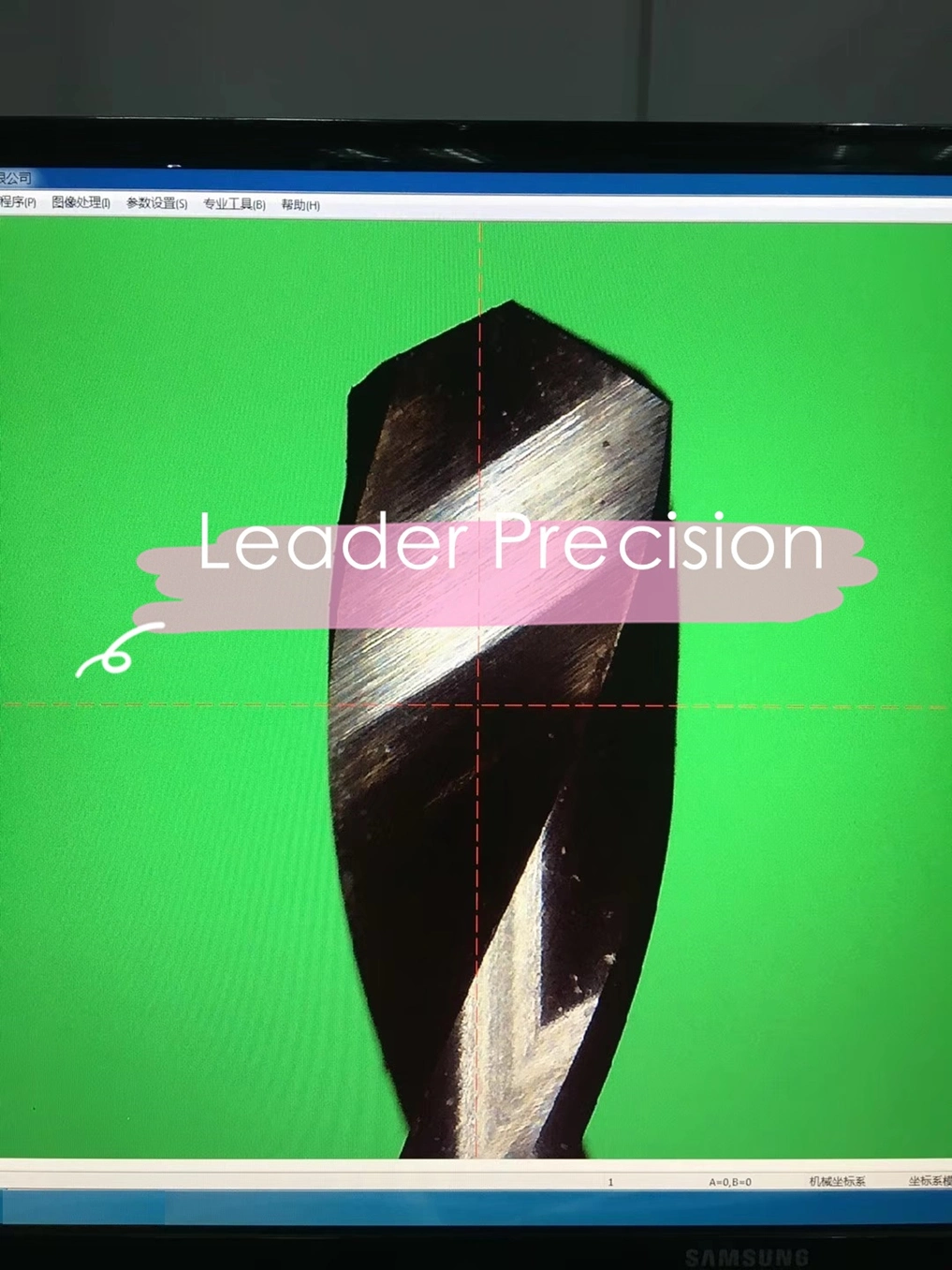

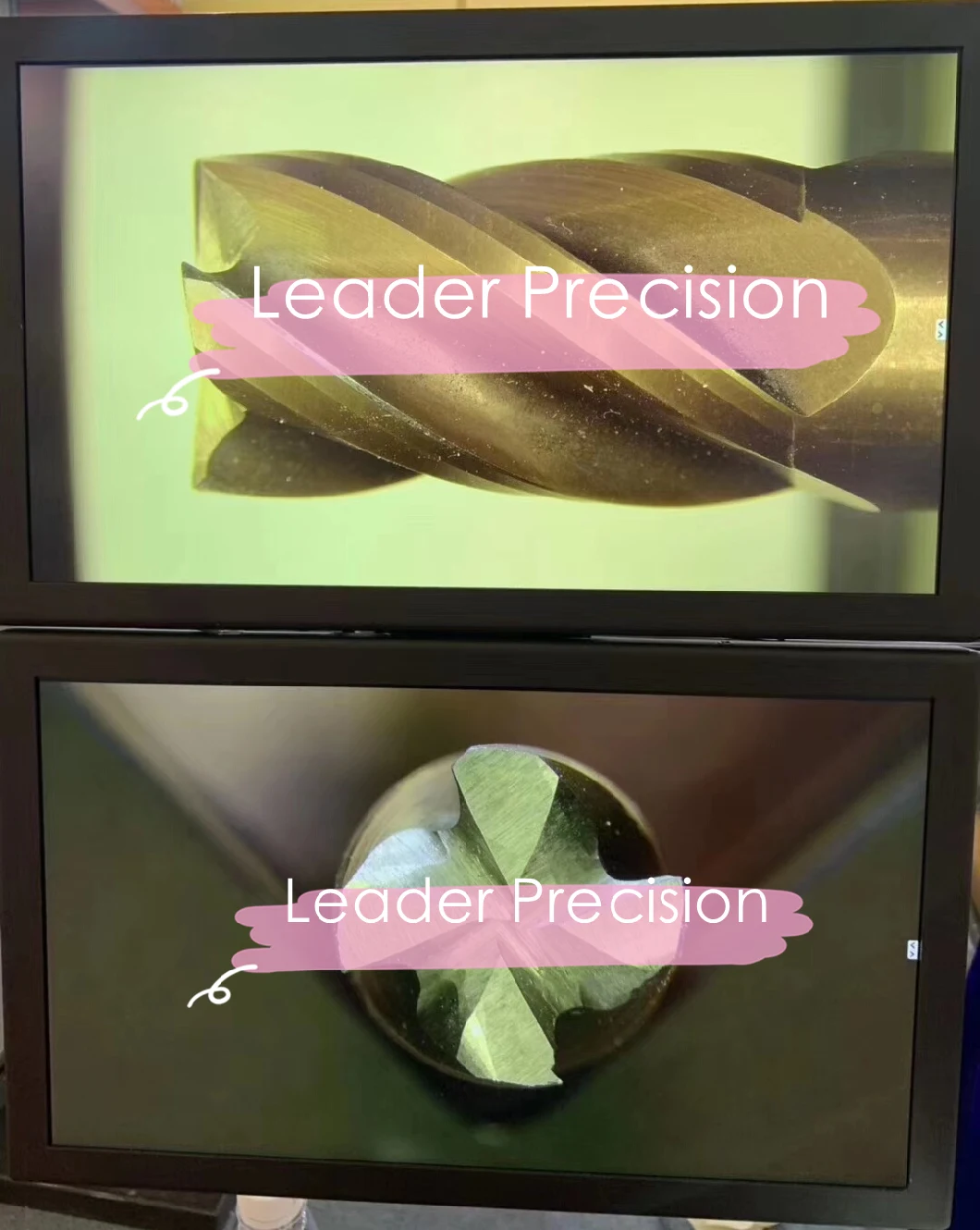

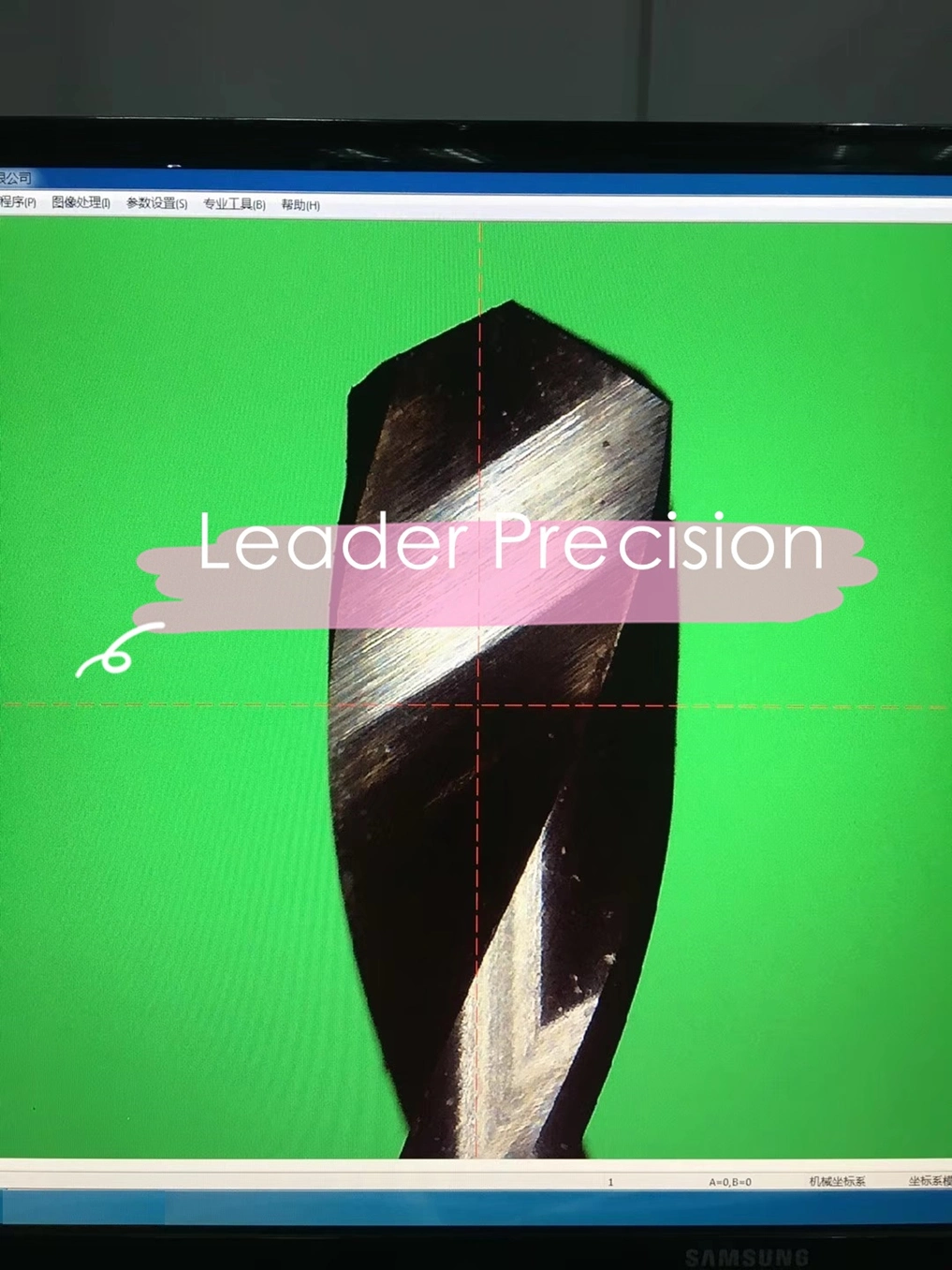

Detailed Photos

Quality System

1. Establish the quality management system based on ISO9001, improve quality inspection, and ensure that all the finished products are qualified.

2. All our measuring machines are with CE certification

3. All our measuring machines are assembled and adjusted with linear accuracy, so that the instrument accuracy is guaranteed by hardware assembly and adjustment to the greatest extent.

4. Our professional technical service team is familiar with the principle, structure, assembly, and software debugging of the instrument, freeing customers from worries!

5. We has provided professional and complete measurement solutions for many large and medium-sized enterprises at home and abroad, and

has won the trust of customers!

After-sale Service

1. Free professional operation training

2. Warranty: 18 months instead of 12 months

3. Regularly upgrade of software is available free

4. Available lifetime technical support

The CNC vision measuring machine is used for 2D measurement, when it adds a probe, it can be used as the Coordinate measuring machine(CMM) for 3D size, such as height, depth, flatness and so on.

CNC Vision Measuring Machine Features & Advantages

1. Servo motor, high positioning accuracy and smooth movement

2. Advanced Navitar 0.7-0.45x zoom lens

3. SENTECH Color 1/2 CCD Camera

4. Joystick and mouse operation, easy to use

5. Granite base 6. Programmable LED cold lights

6. Automatic measuring software

7. Fast Auto Focus

8. Renishaw MCP Probe

Technical Data

| Model | APC300 |

| XY stroke(mm) | 300*200 |

| Z stroke(mm) | 200 |

| Resolution | 0.5µm |

| Measuring accuracy | (2.5+L/200)µm |

| Repeatability | 0.003mm |

| Stage load | 20kg |

| Illumination | Top illumination: LED ring light Bottom illumination: LED light |

| Zoom lens | Optics: 0.7-4.5x Video on monitor: 23-190x (21 inch monitor) |

| Measuring software | 2D measuring software |

| Probe | Renishaw MCP/PH6, option |

| Standard Delivery | ||

| Quick Image Measuring software ZoomView | Sentech Color 1/2" CCD Camera | Navitar Zoom Lens 0.7x-4.5x |

| Capture Card | USB encoder interface | LED Light source |

| Renishaw MCP Trigger Probe kit | ||

| SENTECH Color 1/2" CCD Camera Technical Data | |||||

| Pickup Device & Lens | Display System | TV Lines | Min. Illumination | Power Source | Dimension(mm) |

| 1/2" Color(CCD, C/CS-Mount) | PAL | 480 | 0.2Lux/F1.2 | DC 12V/AC24V | 70*57*260 |

| Optional Accessories | ||

| 0.5x Navitar Additional Lens | 2x Navitar Additional Lens | Calibrations Scale |

| Navitar Coaxial Lens | Navitar Auto Zoom Lens | Optem Auto Zoom+ Coaxial lens |

Detailed Photos

Quality System

1. Establish the quality management system based on ISO9001, improve quality inspection, and ensure that all the finished products are qualified.

2. All our measuring machines are with CE certification

3. All our measuring machines are assembled and adjusted with linear accuracy, so that the instrument accuracy is guaranteed by hardware assembly and adjustment to the greatest extent.

4. Our professional technical service team is familiar with the principle, structure, assembly, and software debugging of the instrument, freeing customers from worries!

5. We has provided professional and complete measurement solutions for many large and medium-sized enterprises at home and abroad, and

has won the trust of customers!

After-sale Service

1. Free professional operation training

2. Warranty: 18 months instead of 12 months

3. Regularly upgrade of software is available free

4. Available lifetime technical support